Fountain Pump Support

How to Videos

How to Articles

Fountain Pump 35-75, 75-150, 150-300, 300-500

ASO Fountain Pump 150 – 300, 300 – 500

Before installing, please read and follow all safety instructions

The fountain pump should be located on a firm and level base in the pond / water fountain. The pump should be covered with water at all times. Make sure that there is ample cable from the mains supply. Place the pump in the desired location; attach the hose connector that is suited to your water feature and connect to your fountain hose. You can soften the end of the hose by immersing in a bowl of hot water; this aids the push-fit to the pump outlet hosetail.

Tip: The larger 1″ hose fitting will give maximum performance when fitted to the pump.

The water flow can now be adjusted by turning the flow control valve – clockwise to increase flow, counter clockwise to decrease flow.

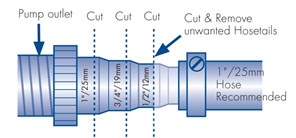

Connecting to hose

Select the hose diameter suitable for your fountain, 1” hose is recommended for maximum flow. Cut off any unneeded, smaller diameter section of the hosetail for best pump performance. See video for more information.

Use the shortest possible length of hose to minimise flow restrictions. Avoid folds and kinks, which reduce flow and performance.

WARNING – Failure to carry out routine maintenance leaving the pump under reduced or no flow conditions (i.e. run dry or blocked prefilter) will result in a shorter pump life and may invalidate the guarantee.

Occasional maintenance

Switch off electricity.

Remove the pump from the fountain/feature or pond (do not use the cable to lift the pump).

Follow steps below: –

- Firmly pull the front and back filter cage from the motor body.

- Thoroughly wash both parts and motor section in fresh water.

- Remove yellow impellor cover by turning counter-clockwise to release lock.

- Then pull firmly away from pump motor.

- Remove impellor from the pump motor. Wash parts with fresh water carefully.

- Replace parts and return to fountain.

Annual Maintenance

Switch off electricity.

Remove the pump from the fountain/feature or pond.

Dismantle pump and examine all parts for wear or damage, replacing any parts

that show obvious wear and/or damage. (See getting to know your pump for parts/description and replacement parts codes.) Particular care should be taken to examine the cable entry point and the cable; if there is any sign of damage the pump should be discarded.

The pump can be run in the pond or feature during the winter but care should be taken to ensure that it is fully immersed and cannot freeze solid. If the pump is not used during the winter, follow annual maintenance procedure and store frost-free in the house or garage until spring.

Follow the steps for cleaning and maintaining. Remove the impellor from the pump and replace with a new one.

Part number:

150-300 – 100521189

300-500 – 100521200

ASO 150-300 – 100521201

ASO 300-500 – 100521202

FAQs

Fountain Pump 35-75, 75-150, 150-300, 300-500

ASO Fountain Pump 150 – 300, 300 – 500

A fountain pump is used to circulate water in a fountain feature, for either indoor or outdoor water features. This type of pump is used to create an attractive visual and audible effect.

A pond pump is used to circulate water around a pond for similar reasons to a fountain pump, but also adds the benefit of oxygenating the pond which is good for any pond life. It can also be used to circulate water to a jet nozzle, a filter, spitter, waterfall or spillway.

To select the correct size Pennington Aquagarden fountain pump, please see the selection videos and select the pump information relevant to the height of your fountain or see the height selection diagrams on the product pages.

No. A fountain does not have to be run constantly. However, water can become stagnant if left still for a long period of time. If you run your pump continuously, remember to top up the water regularly.

See ‘How to store in winter’

Check and top up the fountain reservoir, if the water is low it can produce noise as it sucks in air.

Clean the pump cage to ensure good water flow (see ‘How to Clean and maintain the pump’).

Clean, or replace (if needed), the impellor (this is a spare replacement part). See parts diagram for spares part code.

Check the pump has not run dry due to lack of water in the fountain. The pump is protected by a thermal overload. Turn off the pump, top up the fountain and try the pump again in one hour.

Check the power supply is on.

Check fuses and wiring (see the instructions manual that came with your pump, or locate a copy on the support pages)

Ensure that the pump is fully submersed, and not sucking air due to lack of water in your feature.

Follow routine maintenance procedure (see ‘how to clean and maintain the pump’).

Ensure that the pipe work is not blocked, leaking or is laid so that it gets crushed or kinked.

Keep the height that water is to be pumped from the water surface (called head) to a minimum. The higher the head the lower the flow rate and the more wear on the pump.

Use the largest diameter, smoothest bore hose over the shortest distance and keep hose fittings to a minimum. This removes frictional loss of flow and so increases pump flow rates.

Yes, as long as all electrical safety procedures are maintained.

Spare Parts

ASO Fountain Pump 150 – 300, 300 – 500

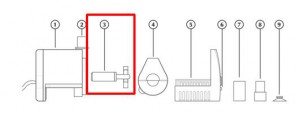

The spare parts available for 150-300 & 300-500 pumps are number 3 below

| No. | Part Description | Code | |

|---|---|---|---|

| 1. | Pump motor | N/A | |

| 2. | Pump outlet | N/A | |

| 3. | Impellor complete | ASO 150-300: ASO 300-500: |

100521201 100521202 |

| 4. | Impellor cover | N/A | |

| 5. | Front pump cage | N/A | |

| 6. | Back pump cage | N/A | |

| 7. | Flow adjuster | N/A | |

| 8. | 1/2″ – 3/4″ – 1″ hose fitting | N/A | |

| 9. | Rubber suckers | N/A | |

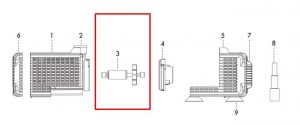

Fountain Pump 35-75, 75-150

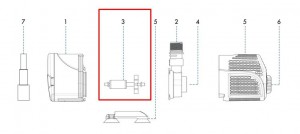

The spare parts available for 35-75 & 75-150 pumps are number 3 below

| No. | Part Description | Code | |

|---|---|---|---|

| 1. | Pump motor | N/A | |

| 2. | Pump outlet | N/A | |

| 3. | Impeller complete | 35-75: 75-150: |

100521187 100521188 |

| 4. | Impeller cover | N/A | |

| 5. | Prefilter cover | N/A | |

| 6. | Flow adjuster | N/A | |

| 7. | 1/2″ hose fitting | N/A | |

| 8. | 3/8″ hose fitting | N/A | |

| 9. | Rubber sucker | N/A | |

Fountain Pump 150-300, 300-500

The spare parts available for 150-300 & 300-500 pumps are number 3 below

| No. | Part Description | Code | |

|---|---|---|---|

| 1. | Pump motor | N/A | |

| 2. | Pump outlet | N/A | |

| 3. | Impellor complete | 150-300: 300-500: |

100521189 100521200 |

| 4. | Impellor cover | N/A | |

| 5. | Front pump cage | N/A | |

| 6. | Flow adjuster | N/A | |

| 7. | 1/2″ – 3/4″ – 1″ hose fitting | N/A | |